NFC Tag Antennas

What does the antenna do ?

An active device (usually a mobile phone) generates a local magnetic field which induces an electric current in the antenna of the passive device (the NFC Tag). This electrical energy powers the NFC Chip which creates a further magnetic field in it's antenna which can be read by the active device (the NFC enabled phone). Thus allowing data to be transferred.

Therefore, NFC tag antennas are not technically antennas at all. They are actually inductors designed to convert nearby magnetic fields into energy.

Antenna performance

There's a number of factors that affect the performance of an antenna and therefore the overall performance of the NFC tag itself. When we talk about performance here, we are referring to the scan distance performance or how far away you can hold your phone for the tag to respond. Let's have a look at some of them :

Size

One the of most obvious performance factors is the size - or more specifically the length - of the antenna. In general (within limits), the longer the antenna, the greater the energy transfer and the better the performance.

We can make NFC tags as small as 3-4mm but they are almost impossible to scan with a mobile phone and require a higher powered USB reader. At the other end, the larger 'credit card' sized tags can be scanned as far as 10cm with some phones.

The thickness of the antenna is not important, which is why NFC antennas can be made thin as they are in labels.

Compared to higher powered USB readers, mobile phones often don't produce much 'power', so there's a limit to the optimum size of antenna. As such, you often get a decreasing performance as the antenna gets larger than the optimum size. For most use cases a 50-60mm antenna is about as large as you can need to go to get the optimum scan performance.

Material

The antenna on an NFC sticker or inlay is made of etched aluminium or very occasionally copper, such as the Midas tag. Copper is more expensive to use than aluminium but performs slightly better and can be made with closer antenna lines (traces) so is only used in the smallest of NFC tags where getting that extra bit of scan distance is critical.

Tuning

The NFC antenna is very carefully designed to resonate at the desired frequency (13.56Mhz) and ensure that this happens as efficiently and as effectively as possible. Badly designed or manufactured NFC tags can have very poor tuning which means that not all tags are produced to resonate at the correct frequency. It's not uncommon on cheap tags to find that scan distance performance can vary from tag to tag.

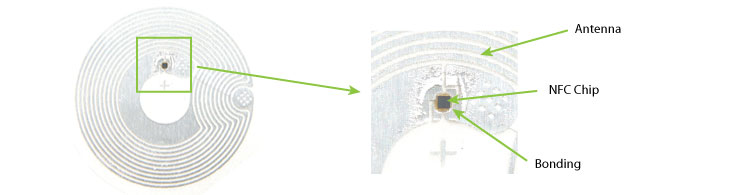

The bond

This is the often the NFC tags' Achilles heel - the bit that gets broken when you bend them too much ! The bond is the connection between the tiny chip and the antenna. It's a small solder electrically connect the terminal on the microchip to the antenna.

On a normal NFC sticker or inlay, the bond will be protected by the substrate or plastic that the antenna and chip is attached to. On inlays, this might be a single sheet and on labels/stickers, this will likely to be two layers of plastic. These layers aim to stop movement on the bond which might cause a break.

If the bond breaks then you can get either no response from the tag (because the chip is no longer attached to the antenna) or worse, intermittent performance depending on factors as simple as temperature changes.

On some tags, such as our garment NFC tag which is intended for use within clothing, the bond is strengthened by the additional of an epoxy glue blob over the top. This increases the strength of the area around the chip and bond preventing possible failure. In addition, the plastic sheets holding the tag together can be made slightly thicker, helping protect against damage by flex.

Coil antennas

While NFC stickers and inlays are made using etched antennas, high quality disc tags and some NFC products (wristbands, keyfobs, etc) use other types of antenna. These usually fall into two categories.

First, and more common, is a coil of copper wire which we typically called a coil antenna but can sometimes be referred to as an 'e-unit'. The performance in terms of scan distance of these can often be very good due to the number of turns and therefore effective length of the antenna. On the downside, it's common to find serious frequency tuning problems on cheaper items which can create scan distance issues.

The second option is a PCB (printed circuit board) antenna. These are typically double sided PCB boards where the antenna is etched on the outside on both sides to increase effective antenna length. Made correctly, these can be very effective, high performance and reliable antennas. However, this kind of performance comes at a price and they are typically only used in the more expensive industrial and disc tags.

From the outside, it's very difficult to tell the difference. However, disc tags and products made with coils and PCBs will almost always perform better and have better long term reliability mainly due to their temperature-related stability over time.

Printable NFC ink

One of the problems with all RFID antennas is that they are expensive to make. While NFC tags will get cheaper, the antenna etching and bonding process means that the unit price of NFC tags is always going to reach a lower limit.

To be cheap enough for NFC tags to make it onto an FMCG or mass market product such as packaging or included in the pages of a magazine, the price per tag has got to fall to a few pence/cents.

Some industry commentators think that this is where printable NFC ink or possibly full circuits might come in. This allows the tag to be 'created' by printing possibly directly onto the surface of the card/plastic of the item.

At the moment, there are a couple of companies testing printed NFC antennas bonded to standard NFC chips. However, Seritag haven't seen anything so far that comes anywhere near the reliability or indeed price point that would be required for a large scale deployment.

A quick intro to NFC tags - what they are, how they are used and the different types of tags

Details of our NFC tag encoding services.

How to order ID / QR code printing on your NFC tags.

How you can order a UID scan of your NFC tags.