The Ultimate Guide to Using NFC Garment Tags for Clothing

vIn today's fashion landscape, the incorporation of NFC tags into clothing, shoes, textiles, wearables, and other attire is steadily gaining momentum. NFC tags serve diverse purposes, from enhancing marketing strategies and providing product information to combating counterfeiting and promoting sustainability within the circular economy.

Brands of all sizes are recognising the potential of smart wearable clothing, and Seritag has played an integral role in numerous groundbreaking projects in this area. This article aims to be your guide to get started.

Overview

When it comes to integrating NFC technology into clothing, there are two primary considerations. The first is to understand how you are going to attach the tags and the second is why you are attaching the tags. These two aspects are interconnected in several ways, but ultimately, it usually comes down to the desired longevity of the tags.

Things to consider before you start :

1. Who will be attaching the tags

2. What are you trying to achieve by adding the tags - marketing, authentication/anti-counterfeit or both

3. Will the tags be generic (all the same), unique to each product line or unique to each individual product.

It's possible that you might not know the answer to all (or any!) of these questions but hopefully this article will help answer or at least provide guidance.

The Product

Garment tags are available in a very wide range of formats from full woven iron-on patches to sew-on buttons. Seritag stock a number of items but many of these are usually made to order. Let's look at the different types.

Hard disc tags

Hard garment 'disc' tags are typically made from PPS plastic. They are extremely durable and can withstand high temperature industrial washing and cleaning processes. Typically available as either a 'button' format with holes so they can be sewn onto items or just as a plain disc which can be attached with a fabric pocket.

If you are looking for a garment tag that will last, then this is the best choice. However, for most domestic use cases, these products are likely to be more durable than required. They are substantially more expensive than the alternatives and because they are hard and cannot flex, they aren't always suitable for use in soft fabrics.

Generally, these tags are 16mm to 25mm in diameter. They are usually made with a coil or PCB (printed circuit board) antenna which makes them very temperature stable but also provides a good scan distance relative to their size. Like any Near Field Communication tag, the larger sizes will scan from a further distance.

Pros

- Durable to washing/cleaning

- Stable and long lasting

- Button format can be easy to attach

Cons

- Expensive

- Rigid and inflexible

'Garment Spec' NFC tags

The 'Garment Spec' tag is a standard NFC clear label with etched aluminium antenna sandwiched between two layers of PET plastic. However, it's strengthened with thicker plastic layers and the addition of a blob of adhesive over the chip to ensure the chip and antenna bond stays strong. For NFC enabled consumer applications - ie, use cases outside the hospitality or healthcare industries - this is rapidly becoming the more common option. There are some variations on this product and standard tags with just a slightly thicker plastic are often called 'garment spec' so it's worth making sure exactly what you are buying.

This type of tag has a number of advantages over the hard PPS disc tags. Primarily, it's a lot cheaper but it's also flexible which means that can be easier to integrate into softer textiles or fabrics.

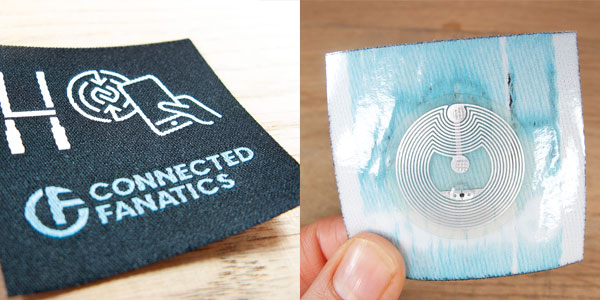

While Garment Spec tags can be manufactured with an iron-on adhesive for direct application to an item of clothing - either with a clear face (so you can see the antenna), a white face or even a printed face - it's more usual for this type of tag to be placed behind a woven label.

The woven or embroidered label can be produced using any standard method and can be generally of any type - overlocked edges, heat trimmed, cotton, polyester, etc. The Garment Spec tag is then simply applied to the back and the woven label attached to the clothing as an iron-on or with stitching. The tags can handle the temporary heat applied during the iron-on process although it's usually best to try and make sure there's a little padding underneath and to the iron face.

Make sure that the woven label is larger than the tag so that you have enough area around the tag for any iron-on adhesive to get a good bond to the fabric - or you have enough margin to sew round the label without going through the tag.

Don't use metallic threads in woven labels as they can interfere with the function of the NFC tags

This type of tag is also a good choice if you are laminating the tag or if the tag is embedded between layers on a shoe, bag or other accesory. For example, if the tags are going in bags, they can be layered between the outside fabric/material and an inner fabric. Just consider any scan distances if the tags aren't being placed close to a surface. NFC tags have a short scan distance and for best usability, you want to get the tags as close as possible to the user's phone.

The common question with this type of tag is 'how long do they last' and there's no easy answer - particularly with wearables. Clearly, tags attached to regular use sportswear which might be washed at high temperature are going to last longer than tags attached to a wool sweater.

Pros

- Economical

- Flexible

- Easy to use and apply

Cons

- Risk of failure in long term use cases

- Not suitable for industrial wash processes

Printed/Thread antennas

There has been a lot of research into printed NFC antennas and woven antennas using conductive threads. This technique would have substantial tactile benefits for smart clothing. This technique is already in use with RFID from companies such as TexTrace (recently becoming part of the ever-expanding Avery Dennison NFC/RFID portfolio). However, RFID technology isn't the same as NFC and reliable, consistent - and importantly cost effective - mass production of woven or printed NFC antennas/tags is likely to be some considerable way off.

In short, right now (November 2023), it's not an option.

Product summary

So which option should you use. If you really cannot have any tags fail under any circumstances, then you should use a hard tag. Otherwise, we usually suggest consider the math.

How many of your users will scan when they first get the smart clothing (hopefully quite a few) - then how many will scan after say five washes. If someone was checking the authenticity of an item, it'll likely be checked at purchase. So let's assume that the number of users scanning after five washes is 5%. Now let's assume that you get a worst case failure rate of a tag of 0.5% after five washes (perhaps those users like to use unusually high temperatures to wash).

Therefore, the chances of someone scanning a dead tag is 0.025% or one person in every 4,000 tags issued. Would that be acceptable.

Choosing your NFC chip

Let's look at the microchip itself. As explained earlier, choosing tags can be divided into two areas - the microchip and the physical item. Different microchips have different features and memory capacity so the choice of chip will be dependent on the use case. Typical NFC chips include the NTAG213, NTAG223/224 or NTAG424. To summarise the key points to consider :

- Memory capacity required

- Authentication / anti-counterfeit features

- Lifespan

Let's look at each of these.

Memory capacity

Seritag very strongly recommend that NFC tags should be used as an ID rather than a data store. This means that the tag is simply a marker to information about the tag/garment held in the 'cloud' on the internet. In this case, the amount of memory required will be no more than a short ID or web link and almost any NFC chip will be suitable.

If you decide to actually store data onto the NFC tag then just be careful. Even the largest NFC tags can't store more than a paragraph of text so consider what might need to be stored now and in the future.

Lifespan

Most of the standard NFC chips, like the NTAG213, have a specified lifespan of 10 years. This is likely to be very conservative under normal use cases but it is what NXP (the chip manufacturer) state. For most garment/clothing use cases, this is going to be more than enough. However, for collectables, furniture or other items, this may not be enough. In which case, other chips might be more suitable. Each case might be slightly different, but as a general guide :

If you are using standard chips then the 10 year NTAG213 can be changed for the 50 year ICODE SLIX / ICODE SLIX2.

If you are using authentication chips, then the 10 year NTAG223/224 can be changed for the 50 year NTAG424.

Authentication / Anti-countefeit

We will cover this further but at this stage it's worth just mentioning that standard tags, such as the NTAG213, can be copied. Authentication tags can't be copied. So if this might present a problem in your use case, then you need to plan for using an authentication chip.

Why use NFC tags in clothing ?

Traceability, authentication, marketing, ownership, recycling, the circular economy... the reasons for using NFC technology are as varied as the garments themselves.

We don't have the space here (and you almost certainly don't have the time) for us to go through all the possible use cases. So we'll cover this in two sections - using standard tags and using authentication/anti-countefeit tags.

To be clear on the difference. Standard NFC tags allow you to store a web link in the user memory and lock it. It can't be changed. However, like a QR code, it can be copied from one tag to another tag using just a mobile phone. For marketing or informational use cases, this is not likely to be an issue. However, if the tag is there to prove that the garment is genuine or perhaps for traceability, you don't want this. Authentication NFC tags generate a unique secure code on each scan which prevents the URL from being copied and used - any previous codes can be identified as 'invalid'.

Use standard tags for identification and information and authentication tags for verification and counterfeit protection

Authentication tags are usually more expensive and also require authentication servers for verification. Seritag and our Ixkio NFC tag management platform can make using these tags very simple, but they will always be slightly more expensive to use than standard tags.

Standard NFC tags

For marketing use cases, standard NFC chips, such as the NTAG213, are the best option. They are cost effective, widely available, very easy to use and available in a lot of different formats. Just get some tags, add your link, attach to the garment and off you go. Common applications include re-ordering information, care and material specifications, special offers and so on.

There's a number of ways that these tags can be used from just a simple link to the home page of your brand to using a full scale tag management system to control the destination and rules to how the scans are handled. The general advice we always give is to start simple. Using tags isn't difficult so try and keep it that way by keeping the scope of the project simple to start with. For example, avoid trying to have different tags for every size/colour/style from day one. Start generic, get used to using the tags then grow your project.

Start simple, then grow your NFC project

Authentication NFC tags

Authentication NFC chips, such as the NTAG424 are designed to ensure that the clothing, garment or accessory they are attached to is genuine. They are more advanced and require advanced encoding/programming and an authentication server to verify.

The chips are encoded with secure 'keys' which allow the chips to generate the unique codes. This key is also held on the authentication server which allows it to check the codes. While they are more advanced than standard, using these tags doesn't need to be complicated and our Ixkio platform has been designed to make using them as easy as possible. We have extensive tutorials and videos on our site on how authentication tags work but in summary :

API

The tags will direct on scan immediately through to the content/brand server and the URL link will include the unique codes. The content/brand server will do a 'behind the scenes' API check using the codes with another authentication server and depending on the response, will display relevant message to the user.

+ Flexible control over the response

+ Tags link direct to brand/content server

- Requires advanced tech knowledge to implement API

Direct Response on Third Party system

The tags will direct on scan to a third party server which will also handle the authentication and send a response back to the user.

+ Can be quick to implement

- Content has to be permanently maintained on third party software

Direct Response on Brand/Content server

The tags will direct on scan to a brand/content server which will undertake the authentication process and respond directly to the user.

+ Full control over the response and authentication procedures

- Substantial technical knowledge required for secure key storage and encryption processes

Redirect

The tags will direct on scan to a management server which will check authentication (and other information such as time of scan, number of scans, etc) and then redirect to the content/brand server (or various pages on the content server) depending on the auth check/other data.

If you're already running a mobile app or website on platforms like Shopify, Wix, or self-hosted, delve into the capabilities of our ixkio tag management platform. With its robust engine, you can effortlessly integrate and leverage tags within your current setup.

Summary

It's simple. If you are thinking about using NFC tags in garments, clothing, shoes or accessories then it's not difficult, there's a lot of options and an ever growing number of reasons why you should.

Speak to us to get your project started today.

A quick intro to NFC tags - what they are, how they are used and the different types of tags

Find the right product in our extensive, hand-picked selection of NFC tags.

Details of our NFC tag encoding services.

How to order ID / QR code printing on your NFC tags.

How you can order a UID scan of your NFC tags.